Hypercube Evolution 3D Printer

Aus ProjectWiki

Version vom 17. Mai 2021, 18:00 Uhr von Mat (Diskussion | Beiträge)

Inhaltsverzeichnis

Parts overview

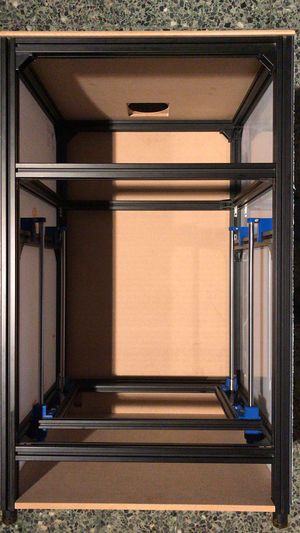

Frame

Dampened Feet

To mount the damper feets, the extrusions need to be tapped. Because the standard 3-flute hand tap does not bite in the first few millimeters, I improvised a 1-flute tap to start the thread and finished it with the 3-flute tap.

Housing

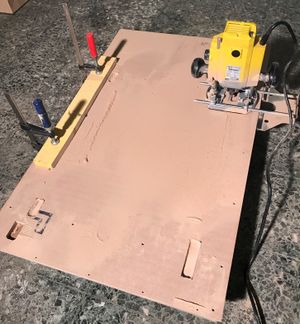

Machining the MDF back-, cover- and base plates

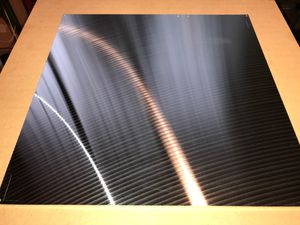

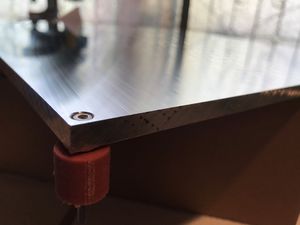

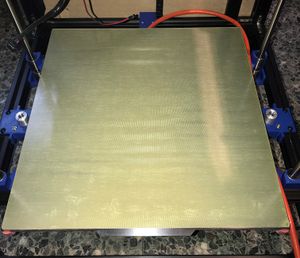

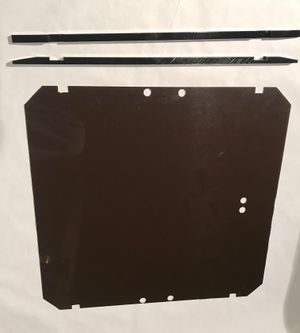

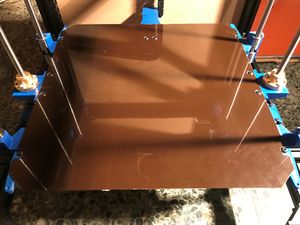

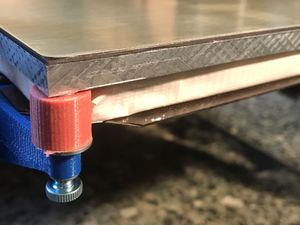

Bed assembly

To hold the insulation material beneath the bed in place, I've made this support plate:

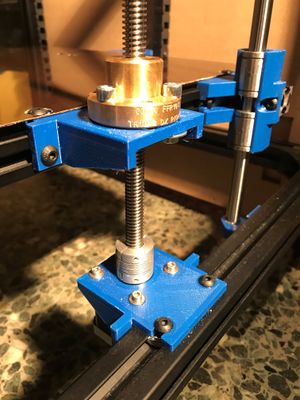

Z-Axis